Building long term partnerships for a sustainable organic cotton supply chain

In order to meet its goal to use 100% organic cotton by 2025, global Luxury group Kering recognized that full awareness of each stage of the supply chain and a whole new way of working was required. As one of its initiatives to address this, Kering partnered with CottonConnect in its quest for greater traceability of its organic cotton supply chain, with a desire to build supply chains that function more as partnership networks than traditional, top-down transactions.

CottonConnect has worked with Kering since 2015, providing agronomic, social and business training for farmers in Kering’s organic cotton programme. The programme connects farmers with Kering’s supply chain, so that the organic cotton produced is directly traceable to Kerings’ brand’s products. Volcom, a modern lifestyle brand in the Kering Group, was seeking to increase the amount of organic cotton used in its products. Volcom had a long-term trusted supplier for its T-shirts who was willing to take cotton fibre from a new source. Using this careful selection of partner, product and supplier, Volcom’s Farm to Yarn initiative was created.

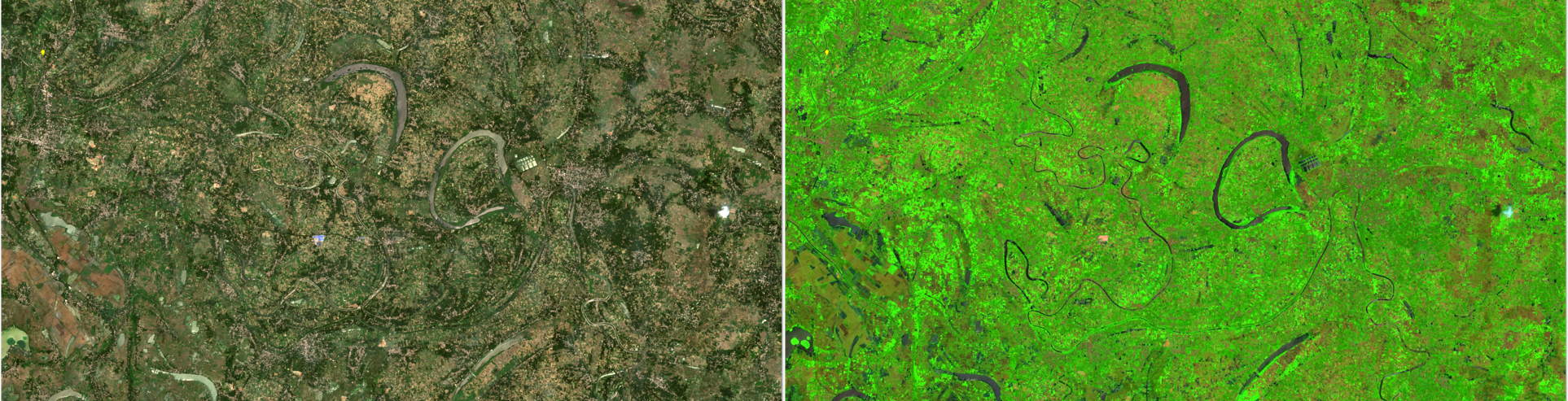

The CottonConnect field programme with Kering consists of three different elements. The Organic Cotton Farmer Training Programme (OCFTP), in its pilot year with Volcom, is focused on training 150 farmers in Madhya Pradesh, India. Fifty women from the community taking part in the OCFTP are enrolled in the Gender Programme: Women’s Rights and Life Skills so that the benefits of both trainings can create positive effects in the community as a whole. In addition, a Farmer Business School was added in the last year of an OCFTP programme with 100 farmers in Maharashtra.

Kering expects the results of the OCFTP to be comparable with a project it ran with CottonConnect in Maharashtra, India in 2015-2017. By year two, compared with conventional farmers, the yield of project farmers had been improved by 16.8%, their input costs reduced by 56.6% and their profits increased profit by 115.6%.

A pivotal moment in the Farm to Yarn initiative’s development was an all supply chain partner meeting in November 2017. In a proactive attempt to foster transparency and create a long term working relationship, Kering, Volcom and CottonConnect arranged a meeting between all the supply chain partners at once. This included the farmer project operator, Noble Ecotech, who also handles ginning, the yarn spinner, Volcom’s sourcing agent, as well as the supplier partner responsible for the fabric and garment manufacturing, Kering’s sustainability team, Volcom’s compliance and supply chain team and CottonConnect.

This meeting allowed direct communication with every member of the supply chain in the room, presenting challenges and opportunities for a new way of working. After this meeting and seeing the benefits of an expanded commitment to traceable organic cotton, it was clear that Volcom would move forward with a partnership arrangement for the long term with the hope of expanding on the work already achieved.

‘A Case Study: Building long term partnerships for a sustainable organic cotton supply chain’ explores the development of a transparent cotton supply chain which enhances livelihoods and contributes to several Sustainable Development Goals. Download the full report here.