Introducing the REEL Linen Code - a new era for sustainable, traceable linen production

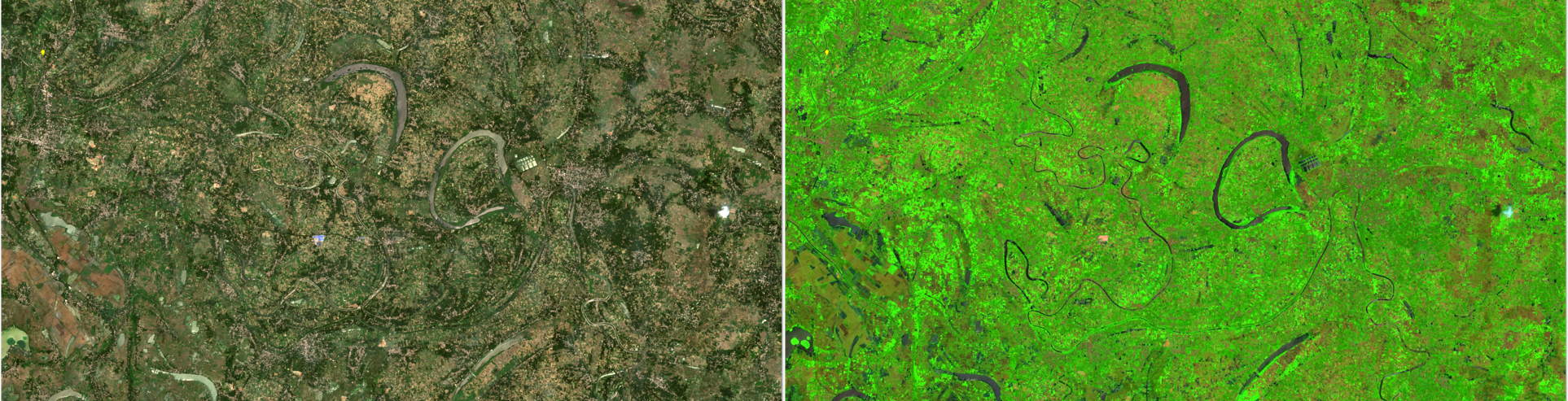

Renewed interest in linen, coupled with consumers’ increasing demand for sustainably produced materials, has led brands to take a closer look at their linen supply chains. However, as the production of linen yarn involves flax growing, scutching and spinning processes, it can be difficult to ascertain if the entire production follows sustainable practices.

Many of the sustainable agricultural practices that CottonConnect promotes through its REEL Cotton and Organic programmes already support regenerative agriculture, such as intercropping and crop rotation, use of bio-compost, farmyard manure, homemade bio-pesticides, producing own seeds, and water saving techniques.

CottonConnect has been working with Kingdom, one of the world’s largest yarn manufacturers, to develop the REEL Linen Code of Conduct that covers both farming and processing (scutching and spinning). Drawing on the expertise of agricultural and development experts in Europe and China, as well as flax producers in France to understand the sustainability challenges in the field, the Code stipulates good practices in management, social and environmental areas.

The REEL Linen Code follows the principles of the REEL Cotton Code, which is the core of agricultural training programmes for sustainable cotton and hemp production.

Compliance with the REEL Linen Code is the focus of CottonConnect’s REEL Linen Programme, a three-year agricultural programme providing farmers with training on sustainable linen farming practices. Flax fibres produced in compliance with the REEL Linen Code are traceable from seed to yarn, supporting the transparency and traceability of brands’ textile supply chains.

“Our vision is ‘to protect our environment, and to meet the needs of the people‘. We are committed to promoting the REEL Linen Code, and urge brands and retailers to put REEL Linen products in their list of sustainably supplied products. To do so, we will work closely with our suppliers, buyers and other stakeholders to drive industry-wide transformation, in order to reduce the industry’s adverse impacts on the world’s water, soil and air, and the human beings themselves, while making it more sustainable,” said Weiming Ren, Chairman and Executive Director, Kingdom Holdings Limited.

Having seen the positive impact of the REEL Cotton Code in cotton production over the last ten years, developing a sustainable code for linen was a logical step. The REEL Linen Code can be used by all stakeholders from farmers to processors to brands, providing assurance of sustainably produced linen. Crucially, the linen fibre produced is traceable from farm to yarn. We hope that the REEL Linen Code will become an integral part of brands’ sustainable sourcing of textiles, contributing to sustainable and resilient supply chains,” said Alison Ward, CEO, CottonConnect.

“When grown right, linen can be a very sustainable crop, creating environmental, social and economic benefits. Kingdom’s suppliers have, over many years, finessed the art of linen fibre cultivation and processing, and Kingdom takes great care to spin these fibres into yarns in the same spirit. With the REEL Linen Code, Kingdom and CottonConnect want to create a trusted and independent assurance mechanism for brands and consumers that their linen was produced in a verified sustainable way, from farm to yarn,” said Christof Walter, Sustainable Agriculture Expert.

The REEL Linen Code has been developed for brands which are committed to sourcing more sustainable linen, including improving environmental, quality and traceability conditions in their supply chain factories and farms worldwide. Brands can include compliance with the REEL Linen Code as a requirement to suppliers of linen yarn and fabric. Brands are also invited to work with CottonConnect to create a sustainable linen programme for their linen production, using the REEL Linen Code.

Read the REEL Linen factsheet for more information.